KAL - Thermal Flow Switch

|

FEATURES

|

GENERAL DESCRIPTION

The KAL electronic flow switch continuously monitors the flow of liquid media. It can be used wherever flows must be monitored with a minimal loss of pressure. The KAL’s one-piece, stainless steel sensor has no moving parts making the KAL very reliable. High strength is another advantage inherent in this design allowing use at high pressures, and virtually eliminating any chance of mechanical damage.

Operation

The KAL design is based on the timeproven calorimetric principle. The sensor is internally heated to a few degrees above the temperature of the medium. Flow of the medium causes removal of heat from the sensor, resulting in a cooling effect. The degree of cooling is a measure of the flow velocity.

The KAL electronic modules allow the user to interface with the sensor to provide access to flow or temperature control in his process. The system can act as either a flow switch only, or a combined flow and temperature switch. Switching is achieved by means of internal SPDT relays.

The microprocessor based design of the KAL distinguishes it from the competition. Full temperature compensation of the switch point is readily obtained through a simple, one-time, calibration procedure. This assures elimination of set-point drift caused by temperature variations in the process liquid.

TECHNICAL DATA

| Material Housing: 304 SS Cable: PVC cladding Cable Gland: Ni-plated brass Cable Length: 6 feet (max. 330 feet) Conductors: 2× 20 AWG Media: Water-based Liquids 60 cSt max. Switching Range Water: 0.2 to 6.6 ft/s Operating Conditions Temperature: 0 to 176 °F Option ”-HT“: 32 to 250 °F Pressure: 1450 PSIG maximum 360 PSIG for models KAL-5132 & 5140 Protection: NEMA 6 Accuracy Display: ± 10% Temperature: ± 2% Reproducibility: ± 2% Response Time Typical: 5.6 seconds Maximum: 10 seconds |

Power: 3 W max. @24 VDC or 24/110/230 VAC Relay: Fail-safe SPDT 3 A @ 250 VAC max. Status Indicator: LED for relay & power Adjustments: For type of liquid and switch point via potentiometer Amb. Temperature Range: 32 °F to 140 °F Protection: NEMA 1 Housing: Polycarbonate L×W×D: 2.95"×2.17"×4.33" Fail Safe Features Power Loss: 10 year memory retention Switch: Relay energizes during normal operation Cable Break: Alarm state signalled Rail Mounting: DIN EN 50022 and DIN 46277 |

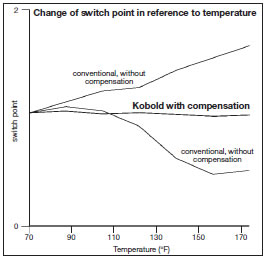

Temperature Compensation

The KAL flow switch uses a microprocessor to compensate for temperature changes through use of an internal look-up table. End-users can easily adapt the equipment to the requirements of their unique installations.

Compared to conventional calorimetric flow switches, the technically advanced design of the KAL provides a switch point which changes negligibly with temperature.

|

Selecting a System The electronic flow switch consists of:

The connecting cable between the two parts may be up to 330 feet long. (with KAL-E300 series units, temperature correction is required with cable lengths above 33 feet.) Controllers Three units are available. Each is compatible with the full series of sensors. Electronic circuitry is located in a standard DIN housing (NEMA 1) for quick installation on terminal rails. |

KAL-E100 Series The KAL-E100 is equipped with a flow KAL-E200 Series Same as the KAL-E100, but with a trend KAL-E300 Series Same as KAL-E200 but with a |

used to monitor the temperature. The specified alarm temperature can be from 0–176 °F. SPDT relays are activated if the flow drops below the specified flow velocity, or if the temperature drops below the specified temperature. Sensors All of the sensor models can be used with any of the three controllers. Selection is a function of:

|

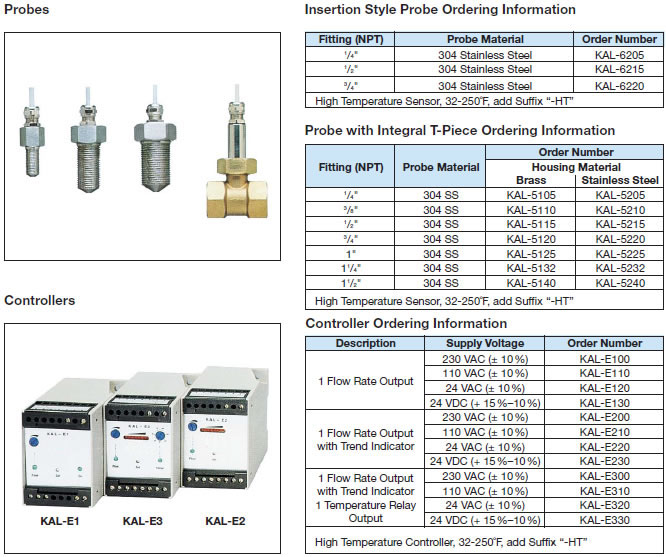

ORDERING INFORMATION

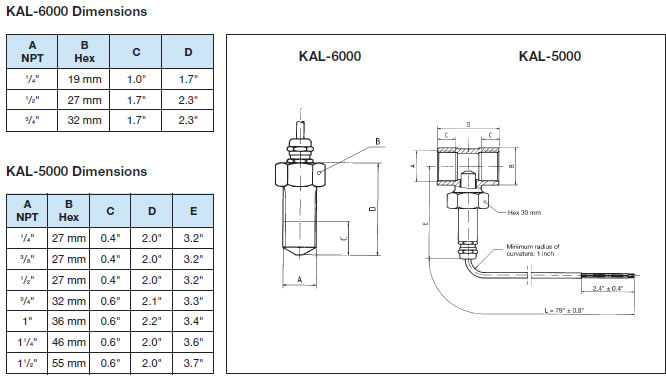

DIMENSIONS