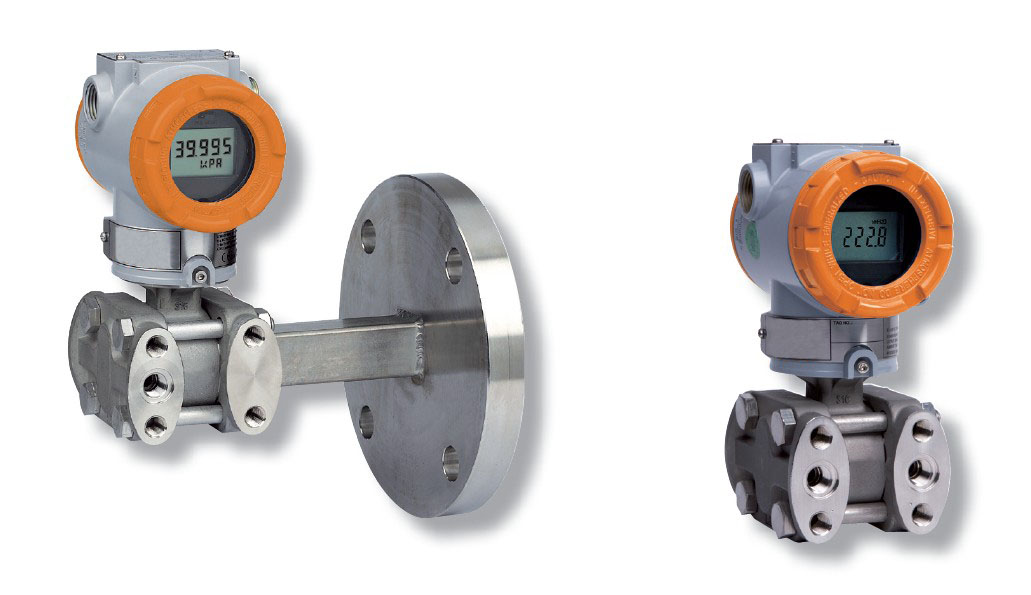

PAD - Heavy Duty Differential Pressure Transmitter

FEATURES

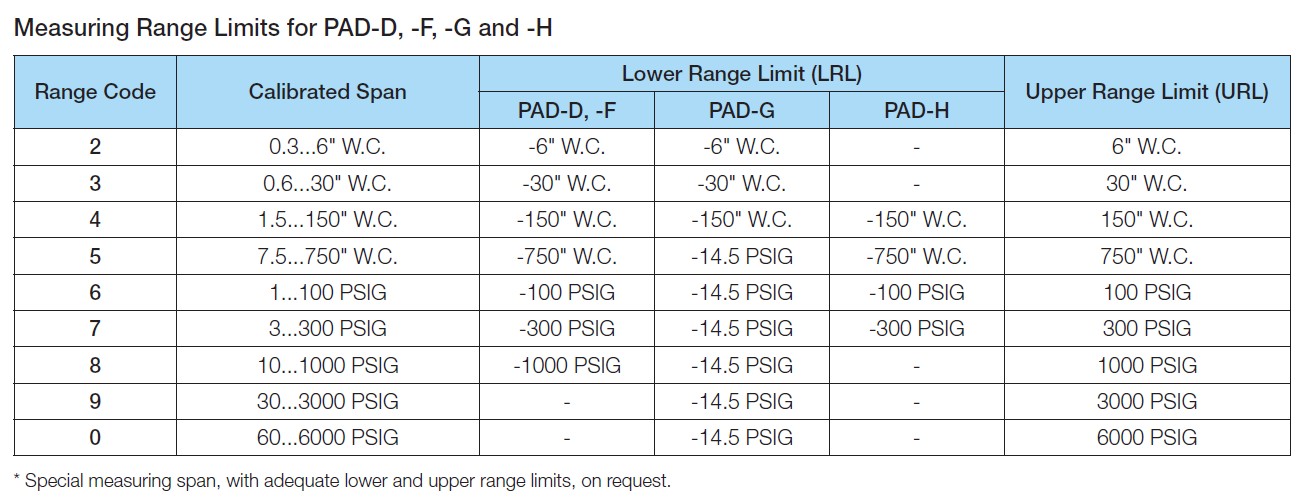

- Span: 0.3" W.C. … 6" W.C. to 60 … 6000 PSIG

- Static Pressure: Max. 4500 PSIG

- tmax: 248 °F

- Process Connection: ½" NPT, ¼" NPT, or Various Diaphragm Seals Available upon Request

- Material: Stainless Steel

- Various Outputs: 4 ... 20 mA or Frequency Output

- Sensor Inputs: Differential, Gauge, or Absolute Pressure

- Digital Communication with HART® Protocol

GENERAL DESCRIPTION

Transmitter Description

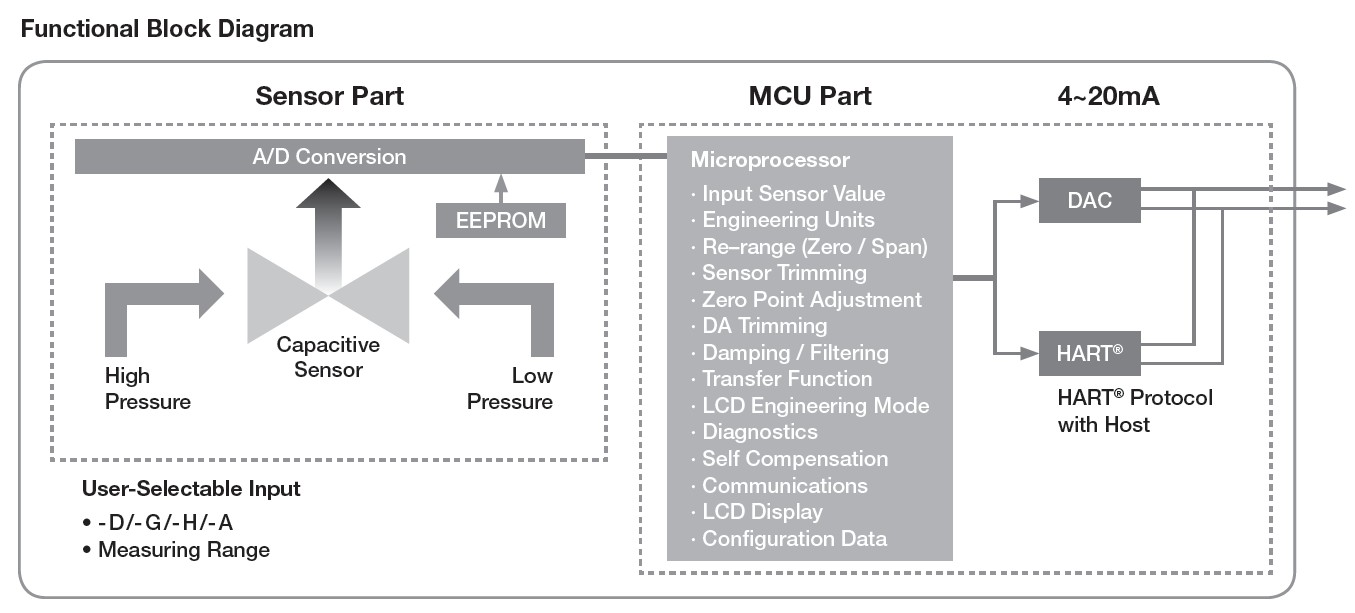

Electronics module

The Electronics module consists of a circuit board sealed in an enclosure. There is an MCU module. an analog module, an LCD module and a terminal module within the transmitter. The MCU module acquires the digital value from the analog module and applies correction coefficients selected from EEPROM. The output section of the MCU module converts the digital signal to a 4…20 mA output. The MCU module communicates with the HART®-based communicator or control system such as DCS. The power section of the MCU module has a DC-to-DC power conversion circuit and an input/output isolation circuit. The LCD module plugs into the MCU module and displays the digital output in a userconfigured unit.

SPECIFICATIONS

Superior Performance

- High Reference Accuracy

- Long-term Stability (0.125 % URL for 3 Years)

- High Rangeability (100:1) for Range 4-0

Flexibility

- Data Configuration with HART® Communicator

- Zero Point Adjustment

Reliability

- Continuous Self-diagnostic Function

- Automatic Ambient Temperature Compensation

- EEPROM Write Protection

- Fail-mode Process Function

- CE EMC Conformity Standards (EN 50081-2, EN 50082-2)

Technical Details

Measuring Principle: Capacitance Sensor (PAD-D, -F, -G, -H), Piezo-resistive (PAD-A)

Measuring Span: 0.3" W.C..6" W.C. to 60…6,000 PSIG bar (Depending on Instrument Version) Zero and Span Values can be set anywhere within the Range Limits. Span must be Greater than or Equal to the Minimum Span.

Accuracy

Range 2: ±0.25 % of Span for 0.1 URL ≤ Span ≤ URL ±[0.24 + (0.008 x (URL/Span)) % of Span for 0.05 URL ≤ Span ≤0.1 URL

Range 3: ±0.075 % of Span for 0.1 URL ≤ Span ≤ URL ±[0.25 + (0.005 x (URL/span))] % of Span for 0.02 URL ≤ Span ≤0.1 URL

Range 4 to 0: ±0.075 % of Span for 0.1 URL ≤ Span ≤ URL ±[0.025+(0.005x(URL/Span))] % of Span for 0.01 URL ≤ Span ≤0.1 URL

Turndown Ratio: Ranges 4 ~ 0 = 100 : 1, Range 3 = 50 : 1, Range 2 = 20 : 1

Process Temp.: -40…248 °F (Approval Codes may Affect Limits. Max. Ambient Temperature at LCD = 176 °F.)

Ambient Temp.: -22…176 °F

Ambient Temp.

Effect: ± (0.019% URL = 0.125% Span)/28 °C

Storage Temp.: -40…185 °F (Non-condensing)

Humidity Limit: 5 %...100 % RH

Pressure Limits (with Silicone Oil)

(Valid for stand-alone instruments only without assembled

diaphragm seals.)

Model D and G: 0…1999.6 PSIG (for Range 2...8)

Model G: 0…5800 PSIG (for Range 9), 0...10875 PSIG (for Range 0)

Model H: 0…4495 PSIG (for Range 4...7)

Model A: 0…72.5 PSIG (for Range 4), 0…435 PSIG (for Range 5), 0…754 PSIG (for Range 6)

Burst Pressure

Model D, G and H: 9990.5 PSIG, 11600 PSIG (for Model G, Range 0)

Model A: 145 PSIG (for Range 4), 580 PSIG (for Range 5), 1015 PSIG (for Range 6)

Wetted Materials

Isolating Diaphragms: 316L SS

Drain/Vent Valves: 316 SS

Flanges/Adapters: 316 SS

O-ring: FKM, PTFE as an Option

Non-Wetted Materials

Fill Fluid: Silicone Oil

Bolts: Stainless Steel

Housing: Aluminum or SS, Flameproof (Ex d) and Waterproof (lP67)

Cover O-ring: NBR

Paint: Epoxy-polyester or Polyurethane

Mounting Bracket: For 2-inch Pipe, 304 SS, with 304 SS U-bolt

Nameplate: 304 SS

Process

Connections: ¼" NPT with 54.0 mm Center Distance for Standard Flanges, ½" NPT with Process Adapter (Option)

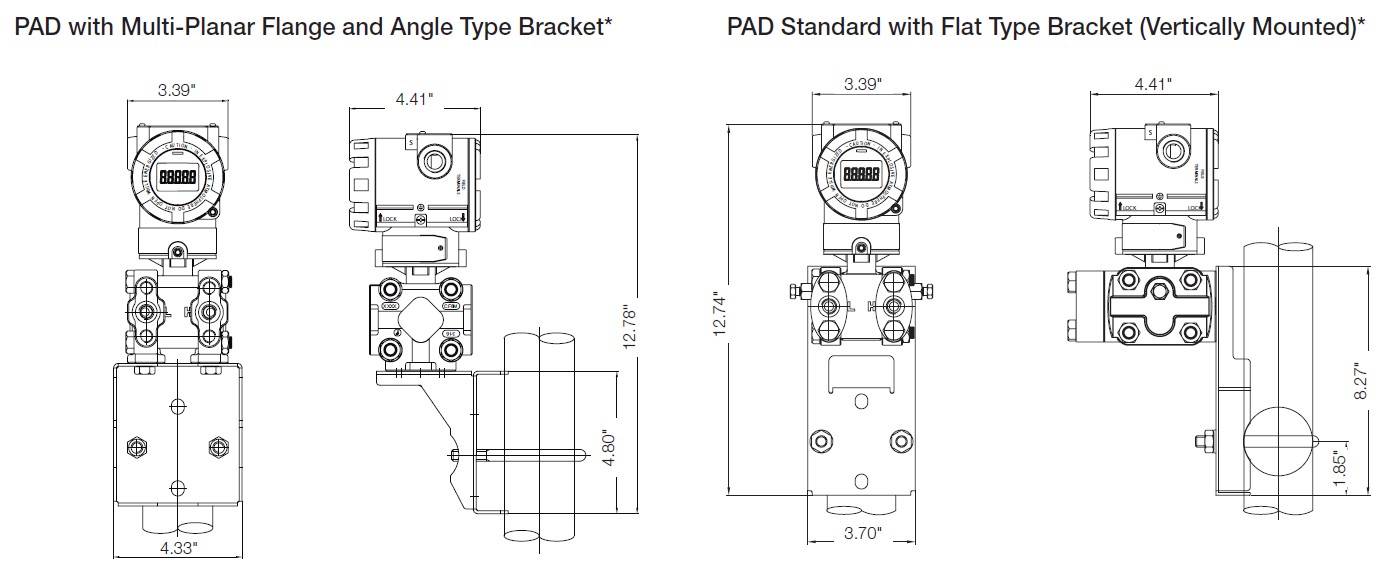

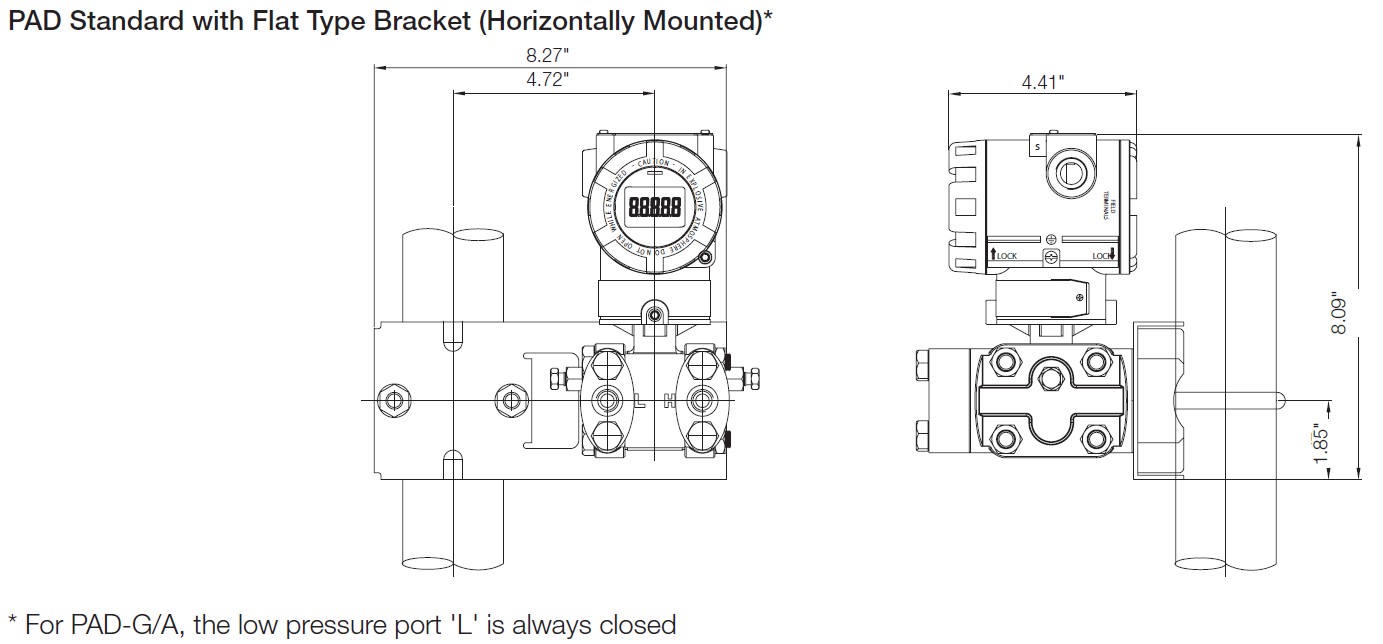

Mount Position: Upright (Process Connection more Flexible by using Multi-planar Flange)

Display: 5 Digit LCD

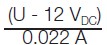

Power Supply: 12…45 VDC, 17.5…45 VDC -HART® Communication

Maximum Load: 250 Ω at 17.5 VDC, 550 Ω at 24 VDC, Max. Loop Resistance =

Loop Load: 0...1500 Ω - Operation, 250...550 Ω - HART® Communication

Failure Mode: Fail High: Current ≥ 21.1 mA, Fail Low: Current ≤ 3.78 mA

Electrical

Connection: ½" NPT Conduit with M4 Screw Terminals (G½ Option)

Output:

- Two Wire 4…20 mA, Configurable for Linear or Square Root Output, Digital Process Value Superimposed on 4…20 mA Signal, Available to any Host that Conforms to the HART® Protocol

- Frequency Output for Flowmeter Model PAD-F with Pulse Width of 10, 50 or 100 ms (Selectable, Negative Going Pulse) Output Type: Open Collector, 30 V, 500 mA max. Pulse Rate: 49 pulses/sec max.

Turn-On Time: 3 seconds

Protection: IP 67 for Standard (Code S)

Weight: 8.6 lb (Excluding Options) Standard 11.8 lb (SS Housing - Excl. Options)

ATEX Approval (Option): II 2G Exd IIC T6 ... T5 (see PAS Datasheet)

II 2G Exd IIC T6 ... T5 (see PAS Datasheet)

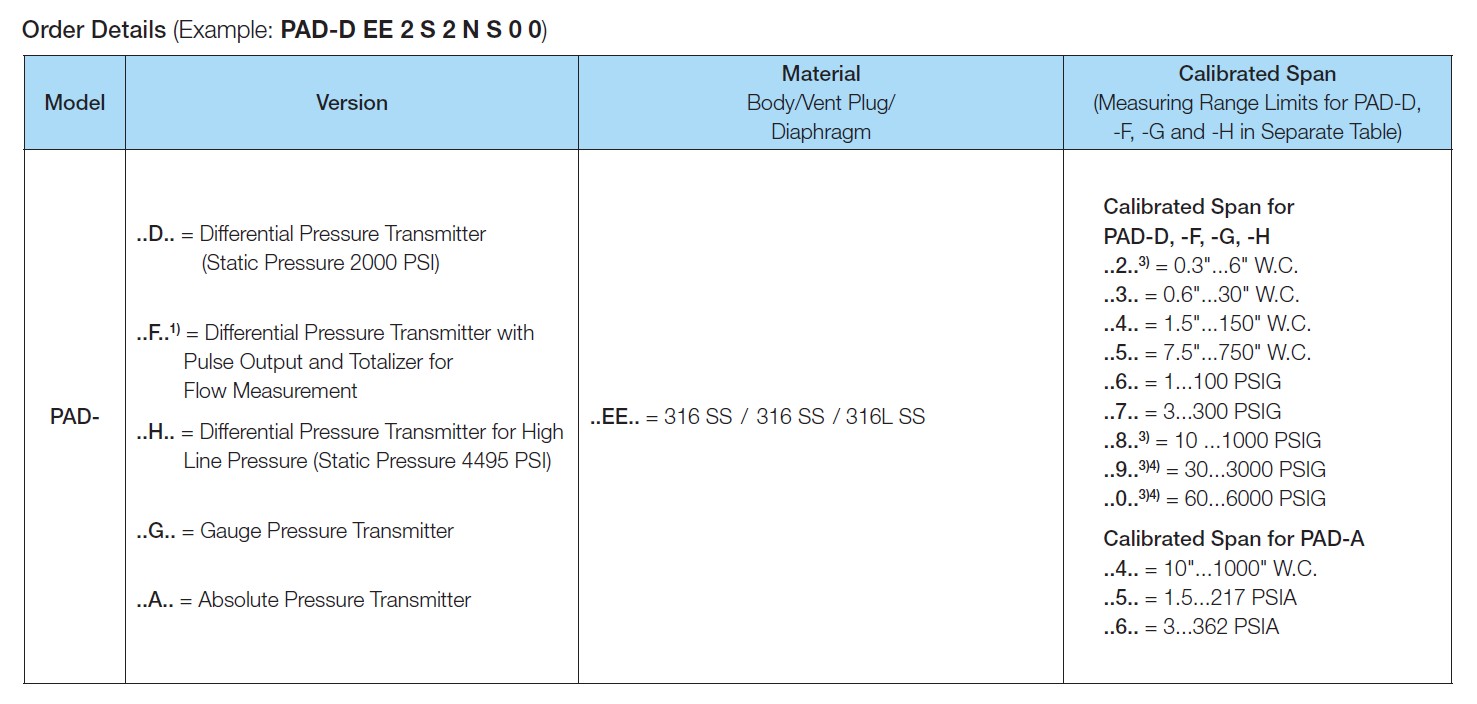

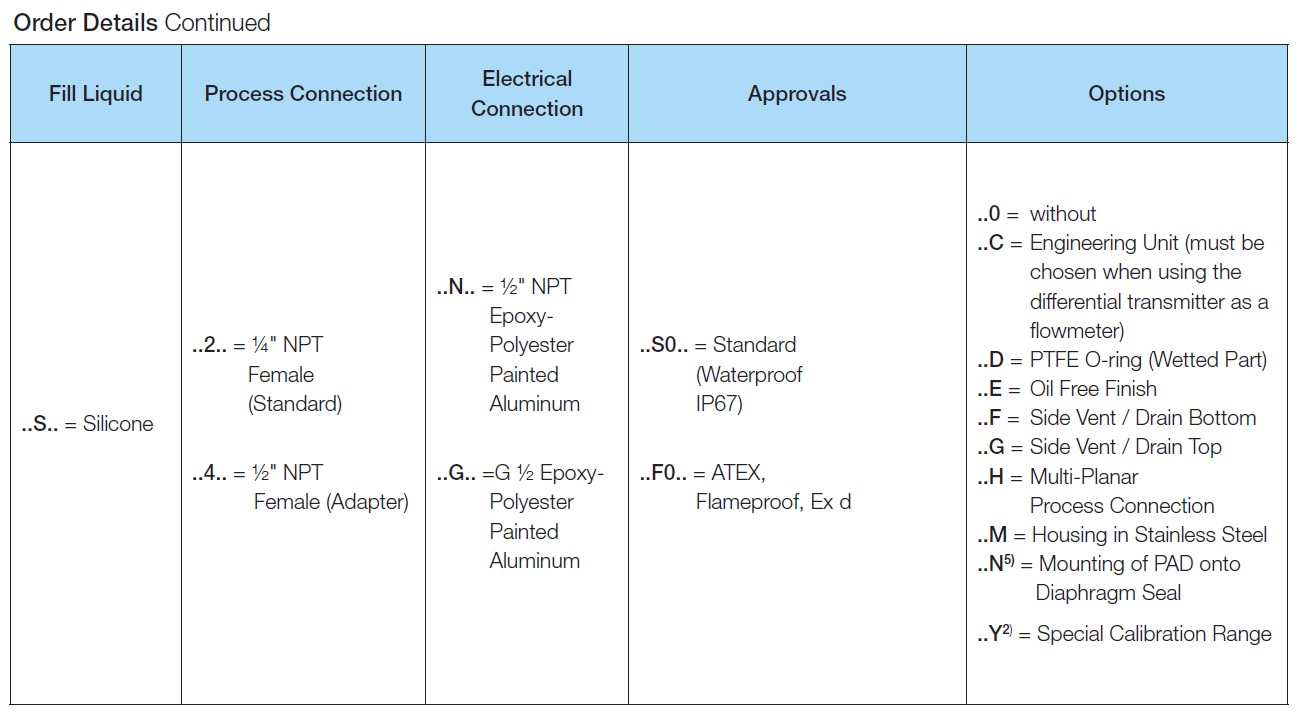

ORDERING INFORMATION

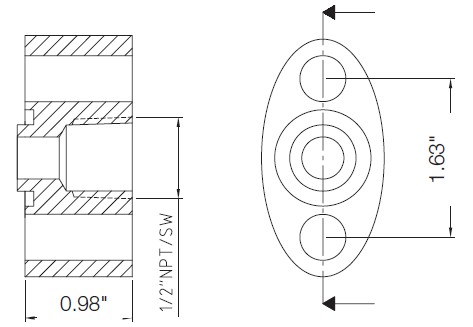

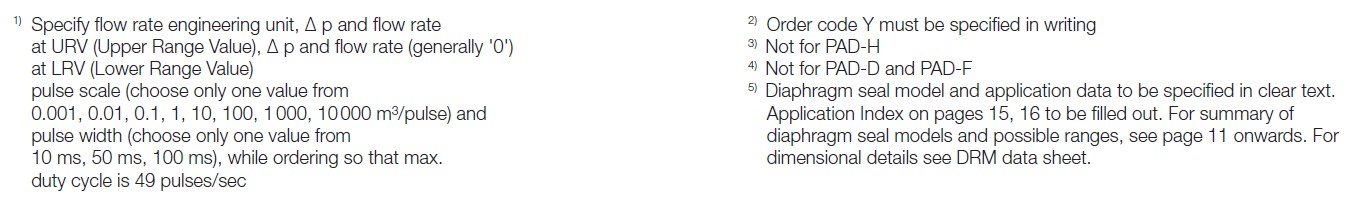

Order Details: Oval Flange Adapter ZUB-PAD-OVF

Technical Details

Material: 316 Stainless Steel

Seal: PTFE

Bolts: 2 x Mounting Screws 7/16"-20 UNF

Connection: ½" NPT Female

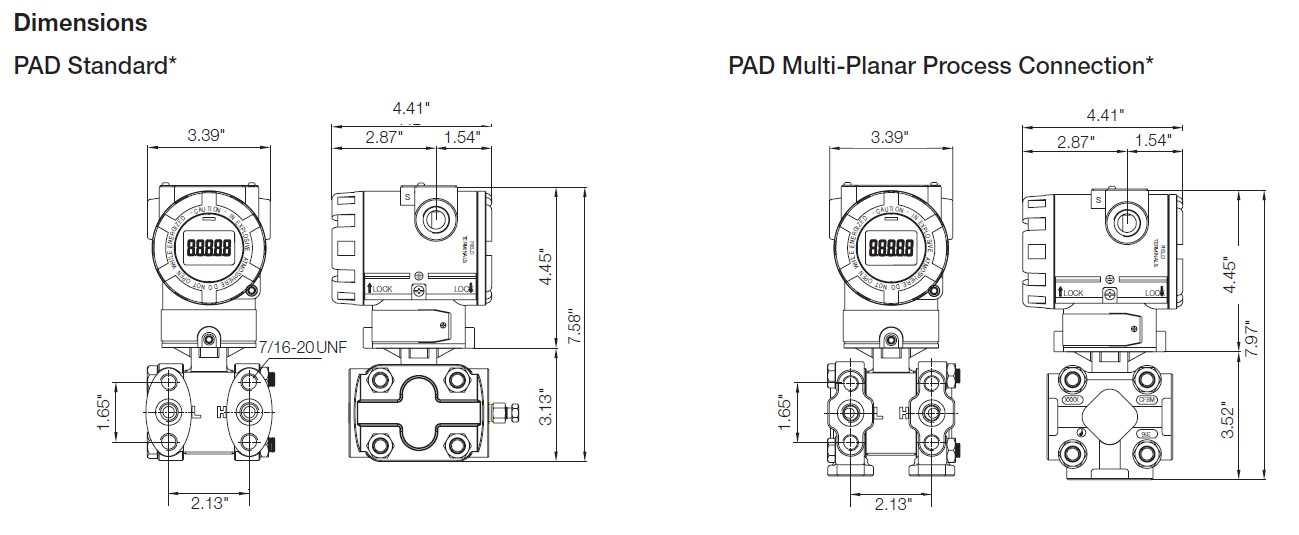

DIMENSIONS