PAS - Heavy Duty Pressure Transmitter

FEATURES

- Span: -14.5 … 21.7 PSIG up to 0…8700 PSIG

- tmax: 248 °F

- Process Connection: ½" NPT, ¼" NPT, or Various Diaphragm Seals on Request

- Material: 316L Stainless Steel

- Output: 4 ... 20 mA

- Sensor Input: Gauge or Absolute Pressure

- Self-Diagnostic Function: Sensor, Memory A/D Converter, Power etc.

- Digital Communication with HART® Protocol

GENERAL DESCRIPTION

Description

Transmitter Description

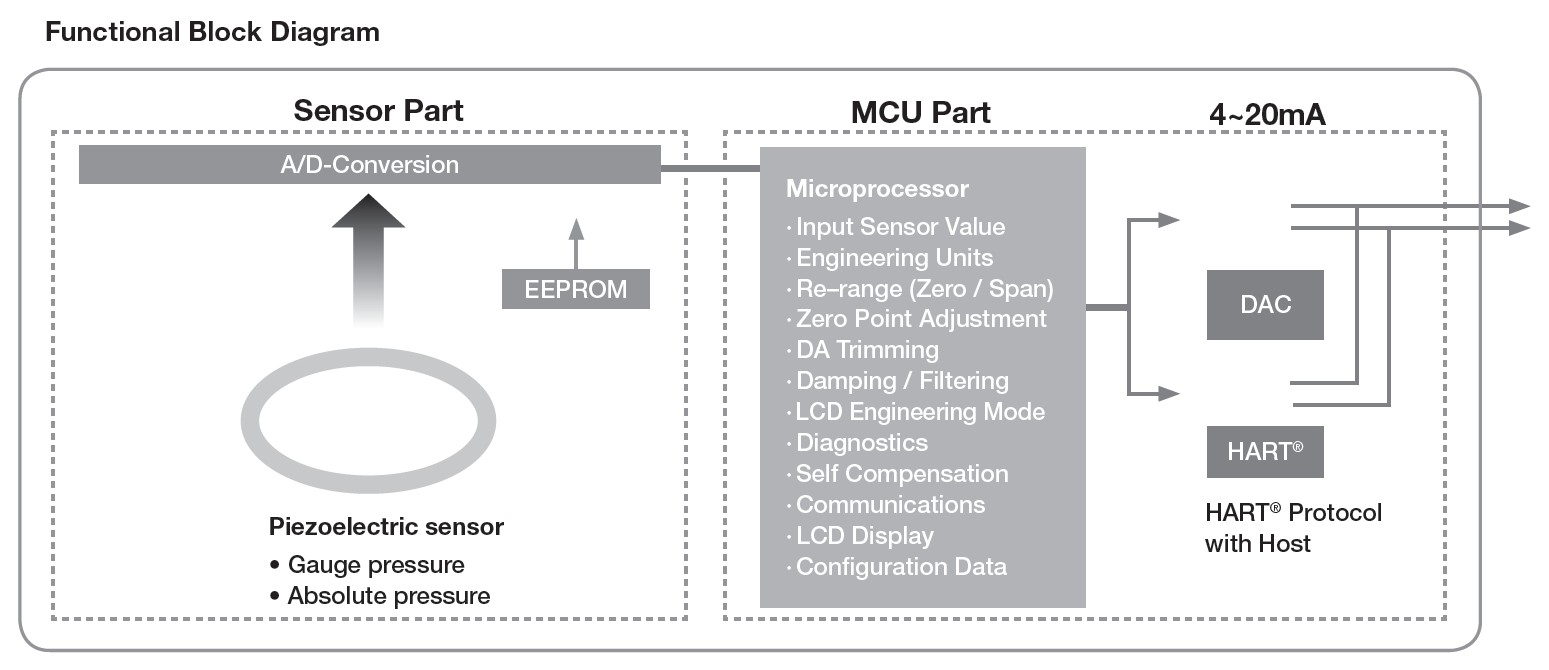

Electronics module

The Electronics module consists of a circuit board sealed in an enclosure. There is an MCU module, an analog module, an LCD module, and a terminal module within the transmitter. The MCU module acquires the digital value from the analog module and applies correction coefficients selected from EEPROM. The output section of the MCU module converts the digital signal to a 4…20 mA output. The MCU module communicates with the HART®-based configurator or control system, such as DCS (Distributed Control System). The power section of the MCU module has a DC-to-DC power conversion circuit and an input/output isolation circuit. The LCD module plugs into the MCU module and displays the digital output in a user configured unit.

Sensor Inputs

The pressure transmitter model PAS is available as a piezoresistive pressure transmitter which measures gauge pressure as well as absolute pressure. The sensor module converts the resistance into a digital value. The MCU module calculates the process pressure based on this digital value.

SPECIFICATIONS

Superior Performance

- High Reference Accuracy:±0.075 % of Calibrated Span

- Long-term Stability

- High Rangeability (100:1)

Flexibility

- Data configuration with HART® configurator

- Measurement of gauge or absolute pressure

Reliability

- Continuous self-diagnostic function

- Automatic ambient temperature compensation

- EEPROM write-protection

- Fail-mode process function

The sensor modules include the following features:

- The software of the transmitter compensates for thermal effects, improving performance.

- Precise Input Compensation during operation is achieved with temperature and pressure correction coefficients that are characterized over the range of the transmitter and stored in the sensor module's EEPROM memory.

- EEPROM stores sensor information and correction coefficients separately from the MCU module, allowing for easy repair, reconfiguration and replacement.

Basic Setups

- The following settings can be easily configured from any host

- that can support HART® protocol:

- Operational parameters

- 4 … 20 mA (zero points/span)

- Engineering units

- Damping time: 0.25…60 sec.

- Tag: 8 alphanumeric characters

- Descriptor: 16 characters

- Message: 32 characters

- Date: day/month/year

Calibration and Adjustment

- Lower/Upper range (zero/span)

- Sensor zero adjustment

- Zero point adjustment

- DAC output adjustment

- Transfer function

- Self-compensation

Self-Diagnostics and Others

- CPU & Analog Module Fault Detection

- Communication error

- Fail-mode handling

- LCD indication

- Temperature measurement of sensor module

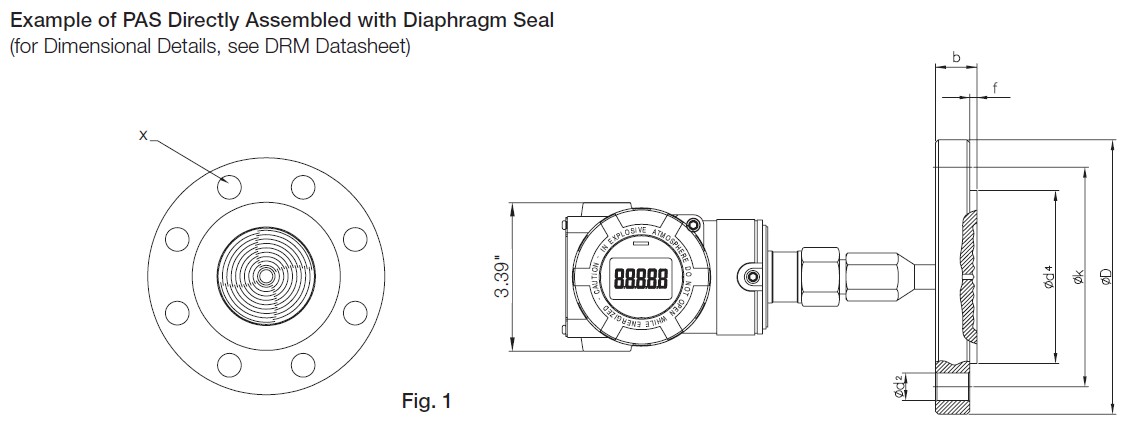

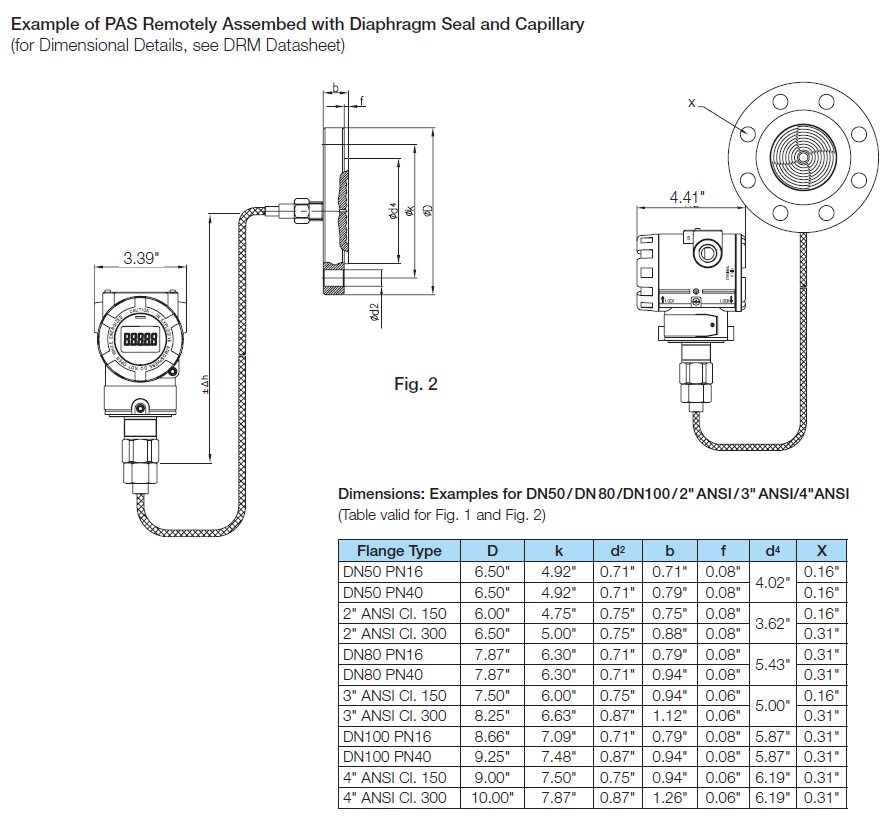

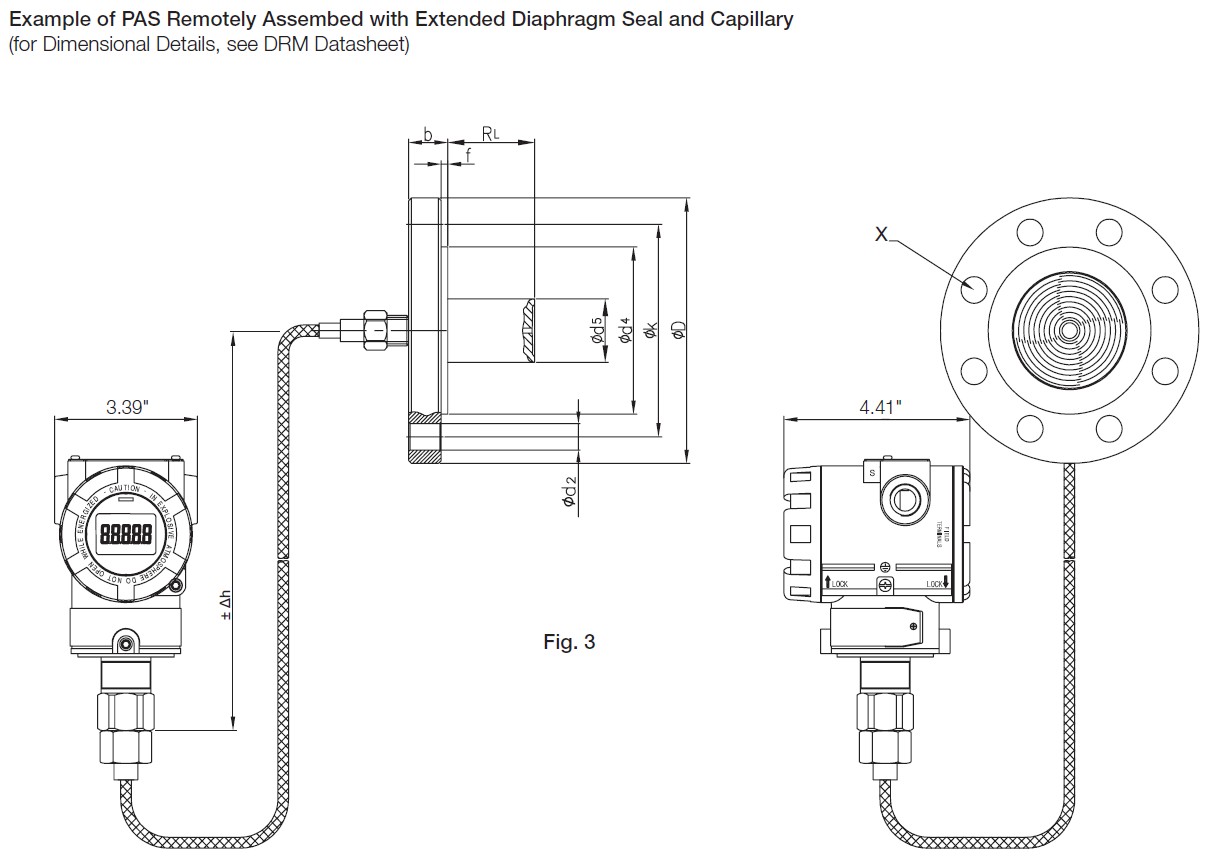

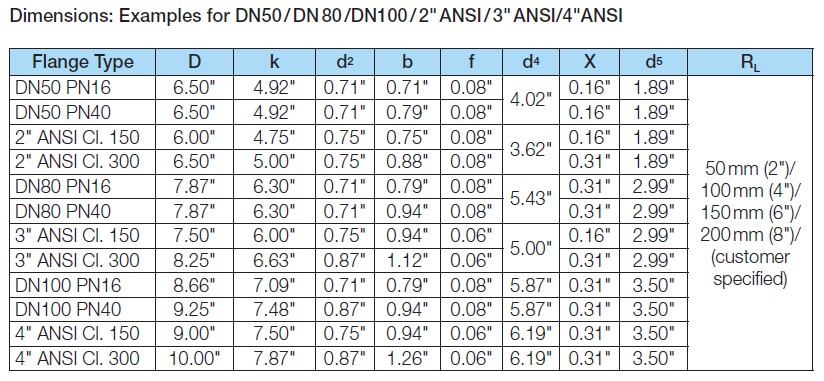

Process Connection via Diaphragm Seals

For connecting the model PAS to different process connections, diverse diaphragm seal versions are necessary. They can be connected to the pressure transmitter directly or via a capillary tube. Depending on the application; different combinations of diaphragm seals, capillary tubes and fill fluids are possible. To clarify those possibilities, the special connections via diaphragm seals should be requested separately from the pressure transmitter.

Technical Details

Technical Details

Measuring Principle: Piezoresistive Sensor

Measuring Span: -14.5…21.7 PSIG up to 0…8700 (Depending on instrument version), zero and span values can be set anywhere within the range limits. Span must be greater than or equal to the minimum span.

Accuracy: 0.075 % of calibrated span

Process Temperature: -40...248 °F(Approval codes may effect limits. Max. ambient temperature at LCD = 176 °F.)

Ambient Temperature: -22…176 °F

Storage Temperature: -40…185 °F (Non-condensing)

Humidity Limit: 5 %...98 % RH

Pressure Limits (with Silicone Oil)

(Valid for stand-alone unit only, without assembled diaphragm seals.)

Model G -14.5...43.5 PSIG (for Range 3)

-14.5...435 PSIG (for Range 4)

0...1552.5 PSIG (for Range 5)

0...5800 PSIG (for Range 6)

0...10875 PSIG (for Range 7)

Model A 0...72.5 PSIG (for Range 4)

0...435 PSIG (for Range 5)

0...754 PSIG (for Range 6)

Wetted Materials

Isolating Diaphragms: 316L Stainless Steel

Connection Thread: 316 Stainless Steel

Non-wetted Materials

Fill Fluid: Silicone oil

Electronics Housing: Aluminum, flameproof (Ex d) and waterproof (lP 67), 316 L SS (option)

Cover O-ring: NBR

Paint: Epoxy-polyester or polyurethane

Mounting Bracket: 2-inch pipe, 304 SS, painted carbon steel with 304 SS U-bolt

Nameplate: 304 Stainless steel

Process Connections: ½" NPT female, ¼" NPT female (via adapter)

Mounting Position: Upright

Display: 5 Digit LCD

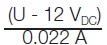

Power Supply: 12 … 45 VDC -operation

17.5 … 45 VDC -HART® communications

Maximum Load: 250 Ω at 17.5 VDC, 550 Ω at 24 VDC

Max. loop resistance =

Electrical Connection: ½" NPT conduit with M4 screw terminals, G ½ conduit with M4 screw terminals

Output: Two wire 4…20 mA, user-configurable for linear output, digital process value superimposed on 4…20 mA signal, available to any host that conforms to the HART® protocol

Update Time: 0.12 seconds

Turn-On Time: 3 seconds

Protection: IP 67 for standard (code S)

Weight: 3.8 lbs (excluding options), 6.3 lbs (st. steel housing option)

Failure Mode: Fail high: current ≥ 21.1 mA, Fail low: current ≤ 3.78 mA

EMC Conformity

Standards: EMI (emission) - EN 50081-2:1993, EMS (immunity) - EN 50082-2:1995

ATEX Approval

(Option): II 2G Exd IIC T6...T4

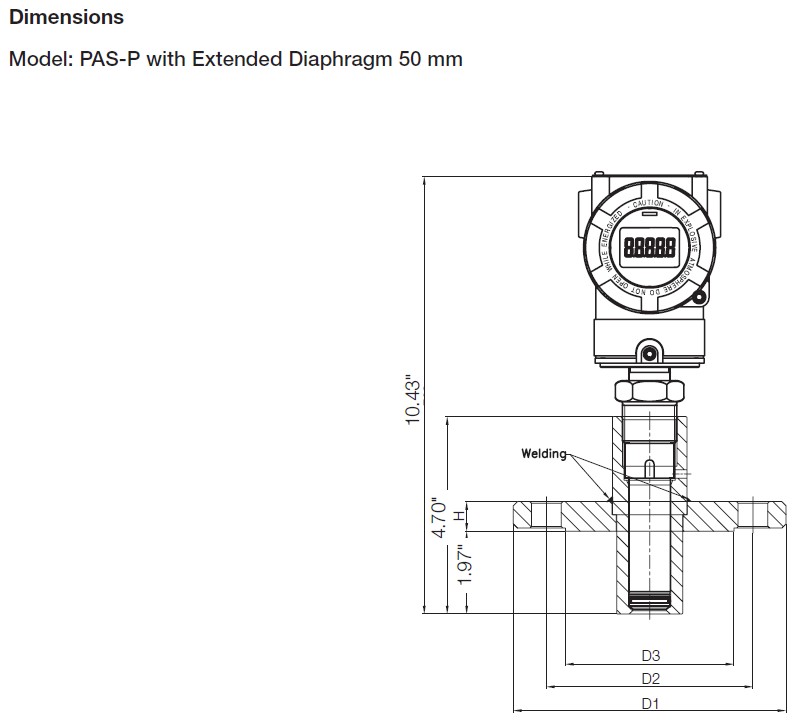

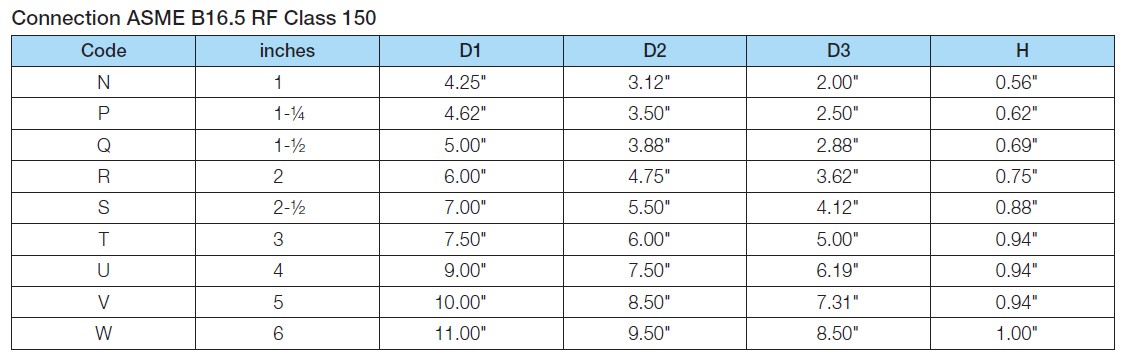

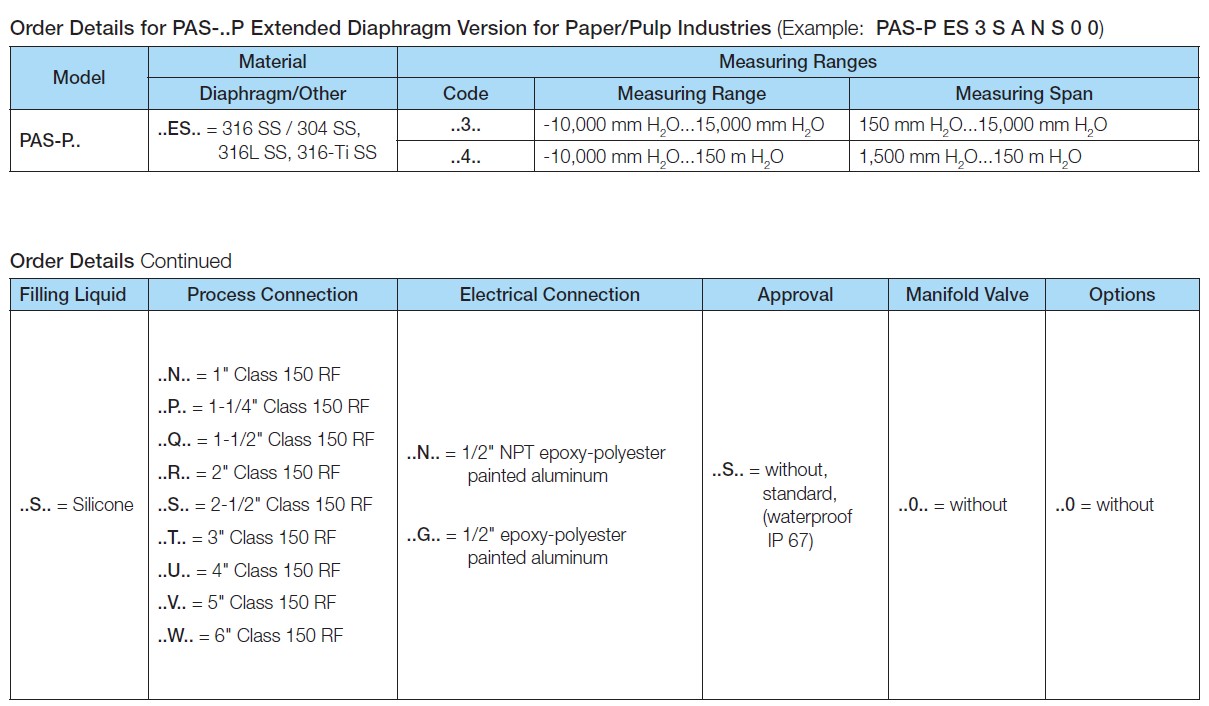

Technical Data for Version with 50 mm Extended Diaphragm

(Model PAS-P, Engineered for the Paper/Pulp Industry)

Application: Level and gauge pressure measurement

Accuracy: ± 0.2% of calibrated span @ 68 °F

Long Term Stability: Application dependent, typically ± 0.125% of URL / 1 year

Process Temperature: 68...95 °F

Ambient Temperature: 68...95 °F

Materials:

O-ring: FKM

Extended Sleeve: 304 Stainless Steel

Process Connection: 316-Ti / 316 Stainless Steel

Other Specifications: Same as standard models

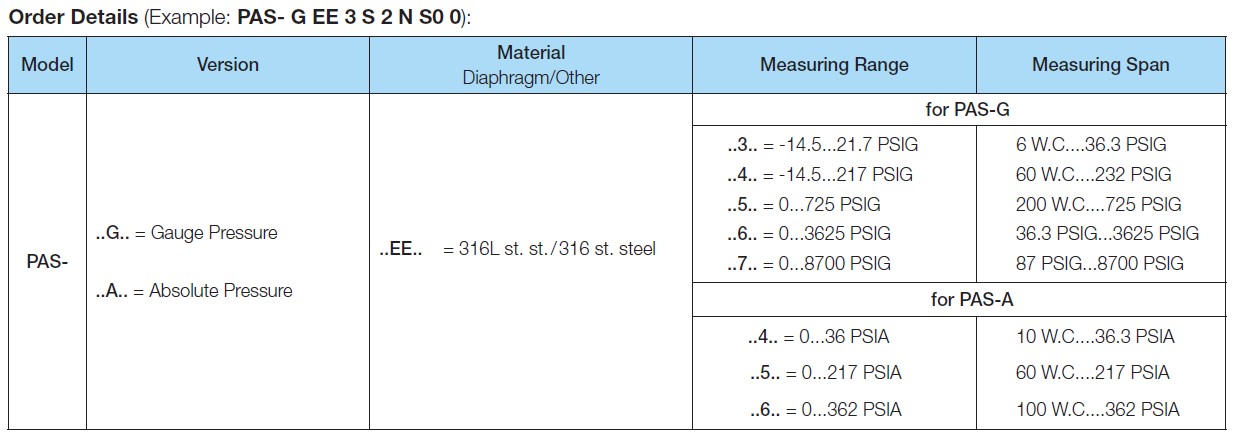

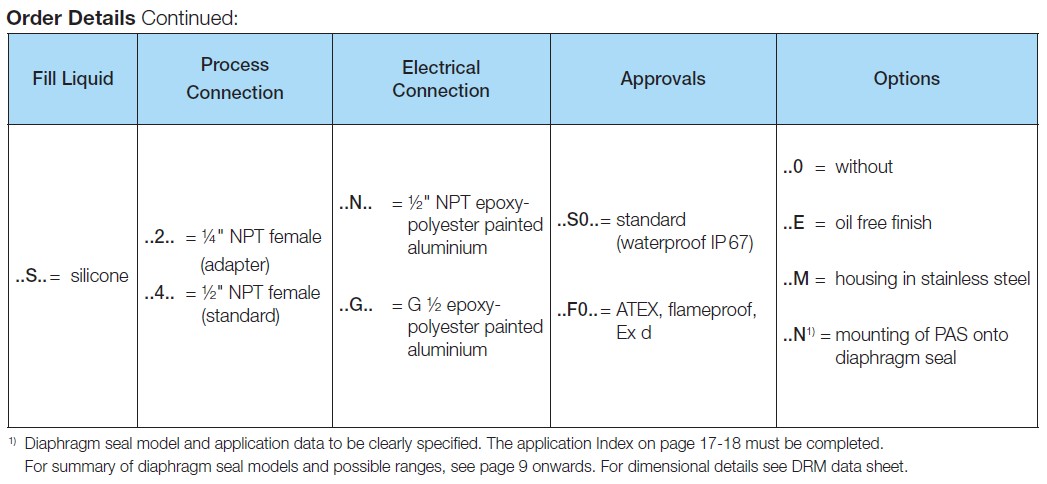

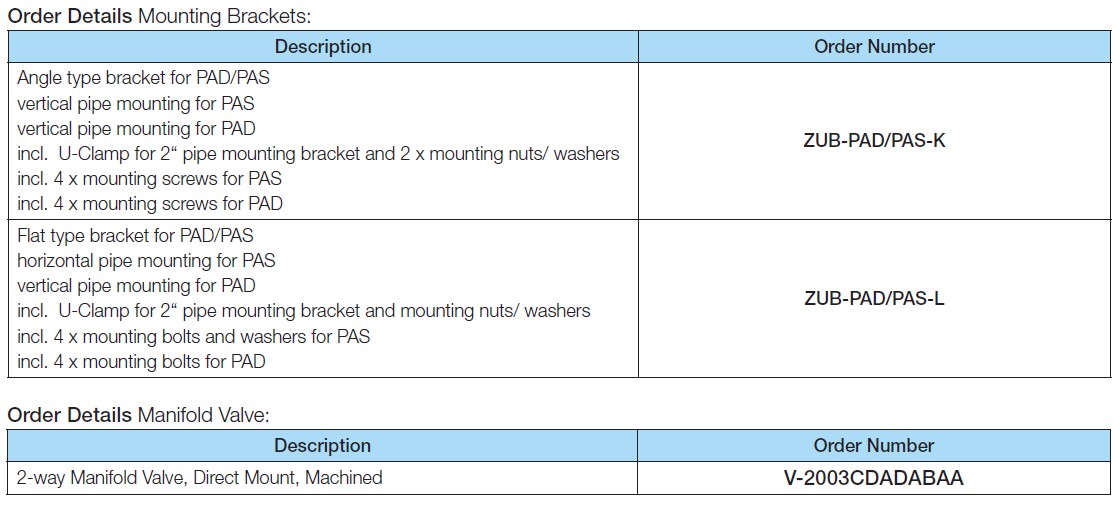

ORDERING INFORMATION

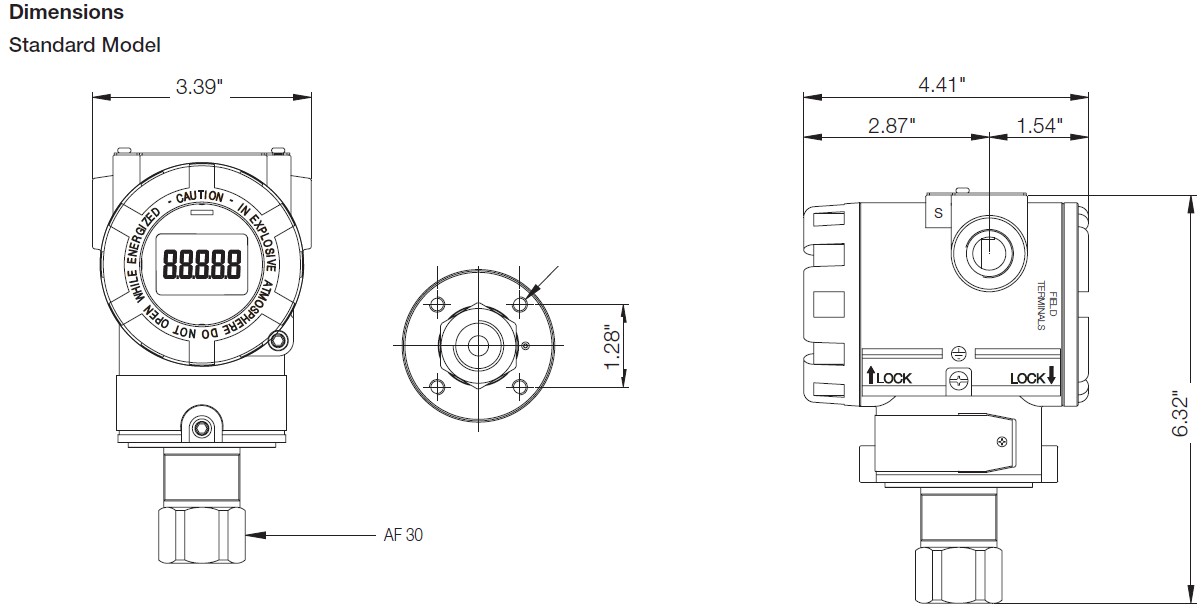

DIMENSIONS