RCM Direct Reading Flowmeters

|

FEATURES

|

|

|

GENERAL DESCRIPTION

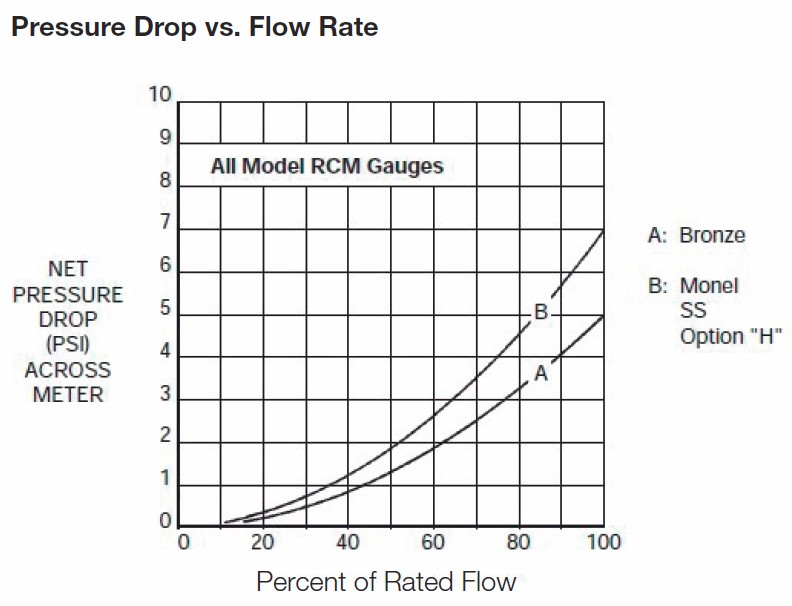

The RCM is a differential pressure direct reading flowmeter, suitable for liquids or gases with low to medium viscosity, low solid content, and compatible with all materials of construction. The RCM is ideal for industrial applications where durability and reliability are important considerations. It is compact, accurate, economical, needs minimal maintenance, and is resistant to damage. In liquid applications of 6 GPM and higher, pulsations snubbers are incorporated into the connecting pressure passages to produce smooth operation in the presence of turbulence.

SPECIFICATIONS

| Accuracy: ± 3% of full scale Rangeability: 6:1 Flow Media: Liquids or gases Media Temp. Range: -30...212 °F (with electrical options) -80...350 °F (without electrical options) Ambient Temp. Range: -30...120 °F Maximum Pressure: 180 PSIG (standard) 400 PSIG (optional) Housing Materials: UV stabilized ABS Standard Option F or F2: Aluminum Option RW3: Fiberglass Reinforced Polyamide |

Body Materials: Bronze, Monel®, or 316 SS Option ES; PTFE also wetted Bellow Materials: Bronze, Monel®, 316 SS, or Inconel® Seal Materials: NBR, FKM, EPDM, PTFE Bellows Cap Material: PPS for low pressure units Same as body material for high pressure and/or high temperature versions Lens Material: Polycarbonate, Option F2: Safety Glass Relay Options: High/Low Alarms Output Options: 4-20 mA, 0-1000 Hz frequency |

|

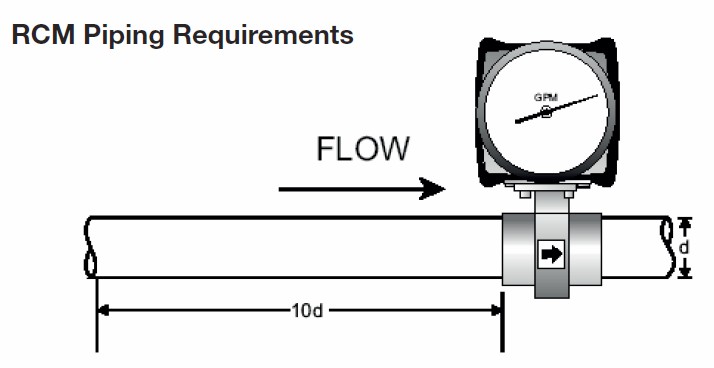

A minimum of 10 PSIG back pressure is required for all RCM models.Upstream piping should have a straight run of at least 10 pipe diameters at the meter inlet connection. If valves are required, they should be installed downstream of the flowmeter. Gas flow models 6000 and 9000 are inlet pressure sensitive and must be regulated to a constant user-selected value at the inlet. |

Output Specifications

| Electrical Rating: General purpose Power Requirements: 24 VDC ± 10%, 50 mA max. Accuracy with Outputs: ± 3% of full scale for horizontal flow ± 5% of full scale for vertical flow Option - ..W (Analog Output): Output: 4-20 mA, 4-wire, proportional to flow Load: 800 Ohms max. Zero: 15% of full scale Span: 30-100% of full scale flow Option - ..W2/W3 (Analog Output): Output: 4-20 mA, proportional to diff. pressure Load: 250 Ohms max. Span: 15-100% of full scale orifice ΔP |

Option - ..X (Alarm Relays): Output: 2 N/O limit relays AC Contact Rating: 3.0 A @ 24 VAC 1.0 A @ 117 VAC 0.5 A @ 230 VAC DC Contact Rating: 2.0 A @ 30 VDC 0.6 A @ 110 VDC 0.5 A @ 140 VDC Option - ..Y (Frequency Output): Output: Frequency signal, 0-1000 Hz, 5 V Peak Zero: 15% of full scale Span: 30-100% of full scale fl ow Option - ..RW3 (Digital Rate/Total Display) Display: Dual line 7 and 11 digit backlit LCD rate and total Output: 4-20 mA, 2-wire, proportional to ΔP Pulse, NPN, 500Hz @ max flow Protection: IP67/NEMA 4X |

ORDERING INFORMATION

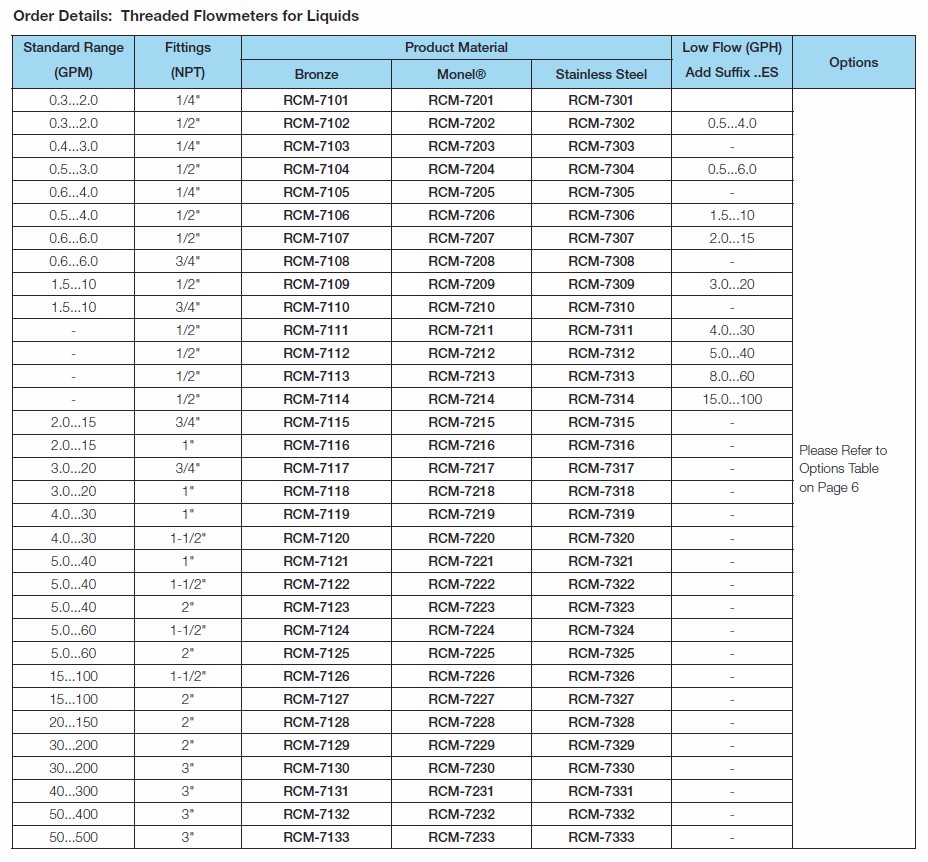

Please note: A minimum of 10 PSI back pressure is required for operation of all RCM models.

For liquid applications, please specify the following with your order: operating/maximum inlet pressure, operating/maximum temperature, and type of liquid; if not water, please specify the specific gravity or density and the viscosity

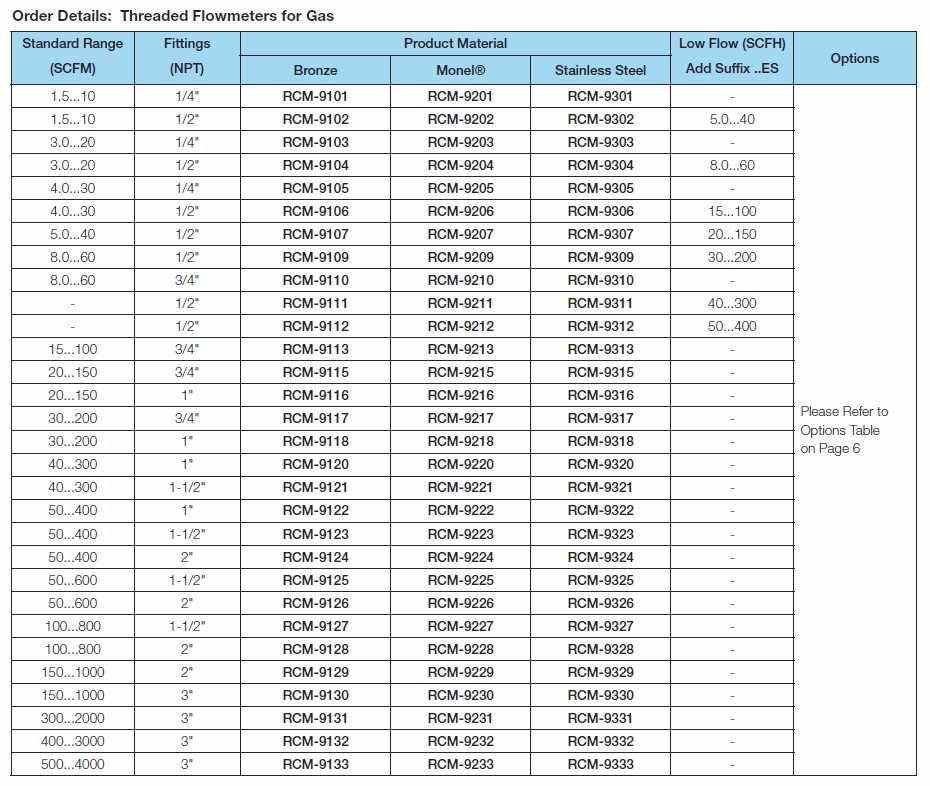

Please note: A minimum of 10 PSI back pressure is required for operation of all RCM models.

For gas applications, please specify the following with your order: operating/maximum inlet pressure, operating/maximum temperature, and type of gas; if not air, please specify the specific gravity or density

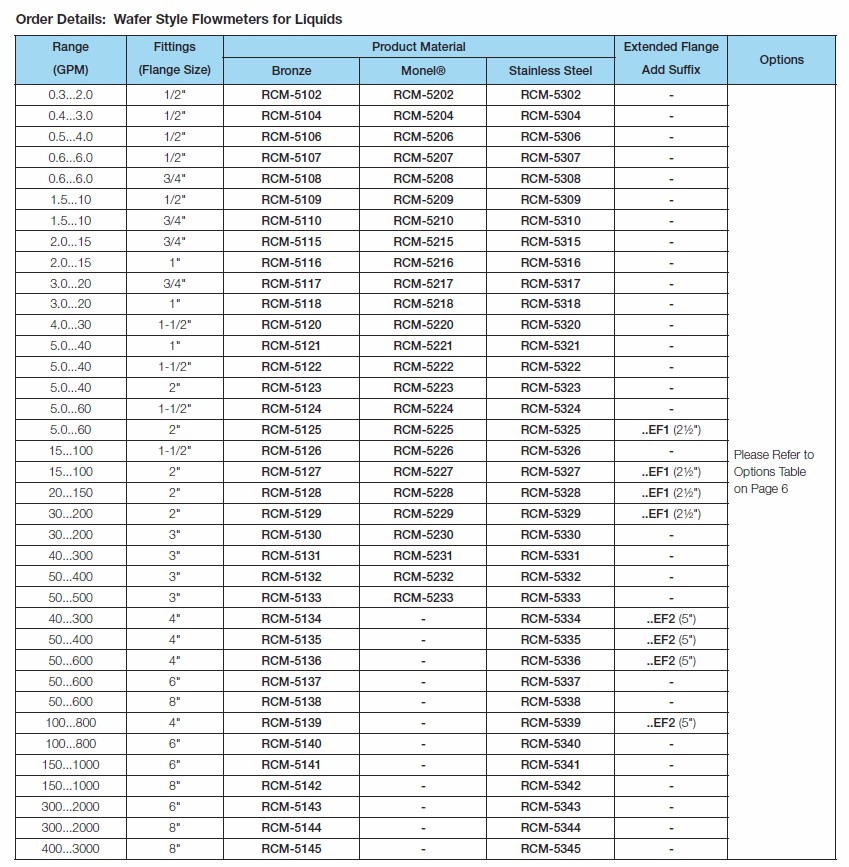

Please note: A minimum of 10 PSI back pressure is required for operation of all RCM models. RCM-5000 series flowmeters are designed for wafer style mounting between two adjoining flanges. The meter will fit between all standard 150 lb or 300 lb ANSI flanges, DIN PN 10 or DIN PN 16 flanges, JIS flanges, and AS flanges. Installation requires flanges, flat gaskets, and flange bolts provided by the user.

For liquid applications, please specify the following with your order: operating/maximum inlet pressure, operating/maximum temperature, and type of liquid; if not water, please specify the specific gravity or density and the viscosity

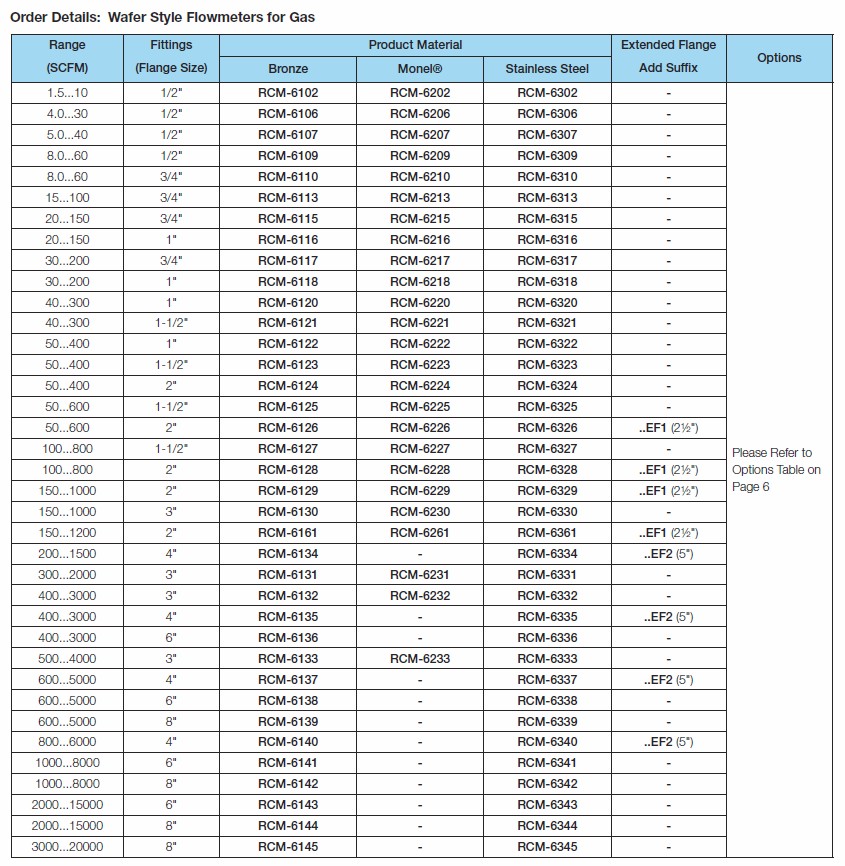

Please note: A minimum of 10 PSI back pressure is required for operation of all RCM models. RCM-6000 series flowmeters are designed for wafer style mounting between two adjoining flanges. The meter will fit between all standard 150 lb or 300 lb ANSI flanges, DIN PN 10 or DIN PN 16 flanges, JIS flanges, and AS flanges. Installation requires flanges, flat gaskets, and flange bolts provided by the user.

For gas applications, please specify the following with your order: operating/maximum inlet pressure, operating/maximum temperature, and type of gas; if not air, please specify the specific gravity or density